At Shaw Industries and Welding Technologies, we specialize in the production of high-quality cutter drums essential for the mining industry. Our comprehensive process involves expert welding and precision machining to ensure durability and optimal performance in demanding environments.

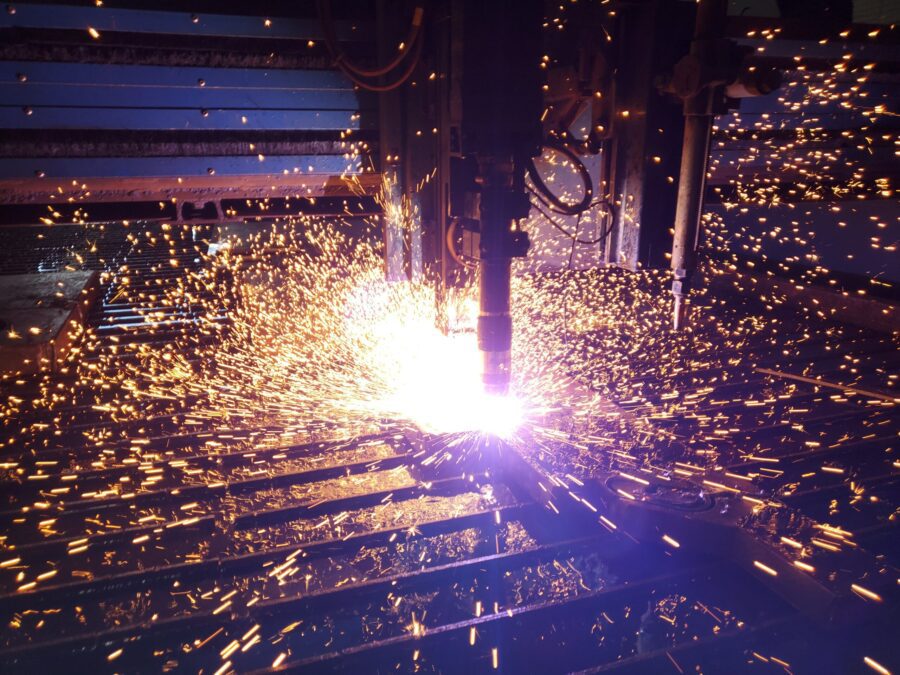

Our welding process begins with the selection of top-grade materials, ensuring that each cutter drum meets the highest standards of strength and reliability. Our skilled welding team meticulously welds and aligns the bit tips on each cutter drum, using state-of-the-art welding techniques to guarantee robust and secure connections. Proper alignment of the bit tips is critical for the seamless operation of the cutter drums, reducing wear and tear and extending the lifespan of the equipment.

Once the cutter drums are welded, our advanced CNC machines precisely shape and size the cutter drums to exact specifications. This precision machining ensures that the cutter drums operate smoothly and efficiently within mining machinery.

At Shaw Industries and Welding Technologies, we pride ourselves on our attention to detail and commitment to quality. Our rigorous quality control measures ensure that every cutter drum we produce can withstand the harsh conditions of the mining industry, delivering reliable performance and exceptional value to our clients.